How can leakage be minimised?

Leakages should be avoided as they affect both air quality and energy consumption. There are two types of leakages:

- Direct leakage past the seals

- Carry-over

The amount of direct leakage past the seals depends on the pressure balance between the supply and extract side. If the pressure difference between supply and extract is zero, then the direct leakage will also be zero. This can be achieved by introducing an extra pressure drop in the extract air.

Carry-over means that air is carried from one side of the rotor to the other as a direct result of the rotation. This means that some extract air is transferred to the supply air and some outdoor air is transferred to the exhaust.

Below is information about how internal leakage is minimised in Swegon air handling units and how the internal leakage is measured correctly.

How leakage is minimised in GOLD units

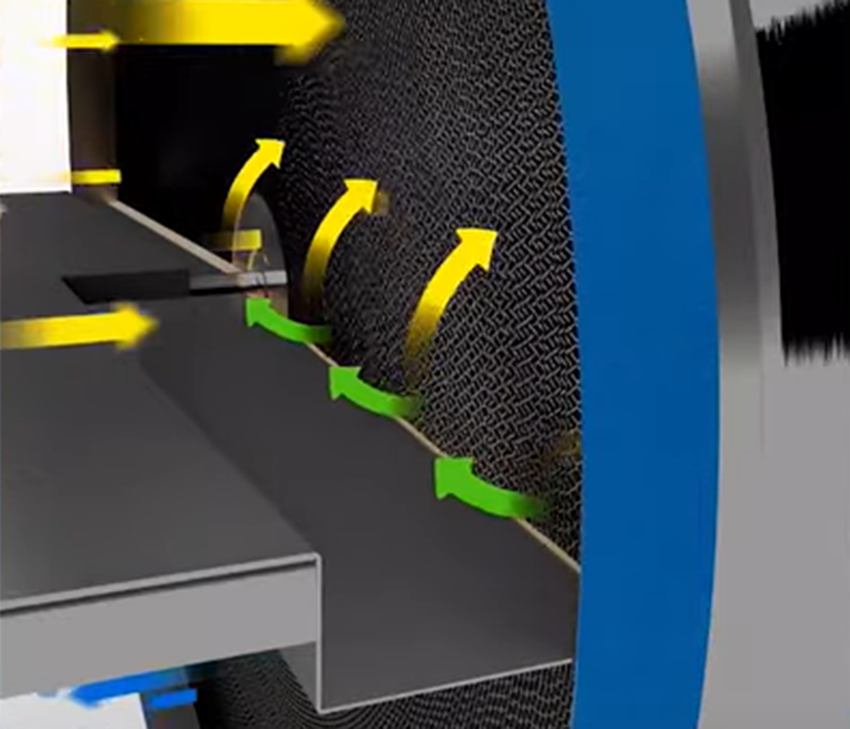

Purging sector

The carry-over can be minimized by use of a purging sector; which is a plate that blocks off a sector of the rotor for the extract air and lets a small amount of outdoor air purge the rotor of the extract air. This eliminates the carry-over of extract air to supply at the air velocity for which the size of the purging sector is designed for. At lower velocity, there will be a small amount of carry-over.

Eurovent´s guide "Air Leakages in Air Handling Units" is recommended for further reading.

Carry-over control

The GOLD control system IQlogic features a function that controls the speed of the rotor according to the air velocity in order to ensure correct purging. By matching the rotor speed to the air flow, slowing down the rotor if necessary, transfer of extract air to the clean supply air is minimized.

Pressure balance

For the purging function to work, it is necessary to have a pressure difference to drive the airflow through the sector. This requires the pressure before the rotor on the extract side to be lower than on the supply side after the rotor.

In GOLD units, the pressure balance can be measured using the tappings provided, and adjusted using the perforated pressure plates included in the unit.

Air Quality Control

The GOLD control function includes an option that ensures correct pressure balance even when the external pressures are changing. A pressure sensor is used to control a damper on the extract inlet so that the correct pressure is maintained continuously. This is ideal for DCV systems.

How internal leakage is measured

OACF and EATR

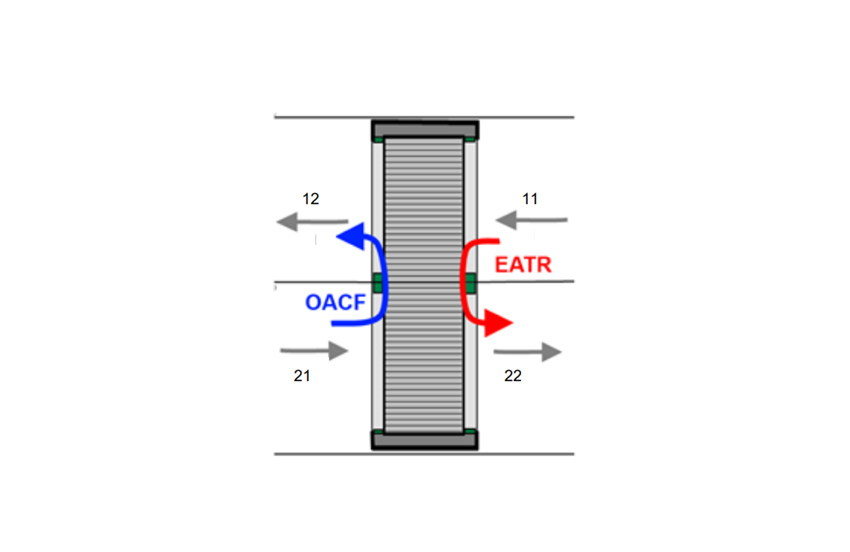

The most established factors for characterising internal leakages in rotary heat exchangers are EATR and OACF, which are both defined in EN 16798-3.

EATR defines how much extract air leaks to the supply air. OACF defines the ratio of outdoor air to supply air and is a measure of the leakage between outdoor and exhaust air.

EN 308 provides methods for measuring the performance of heat exchangers, including OACF and EATR. All Eurovent certified air handling units are measured in accordance with EN 308.

Illustration:

Eurovent

SFPv

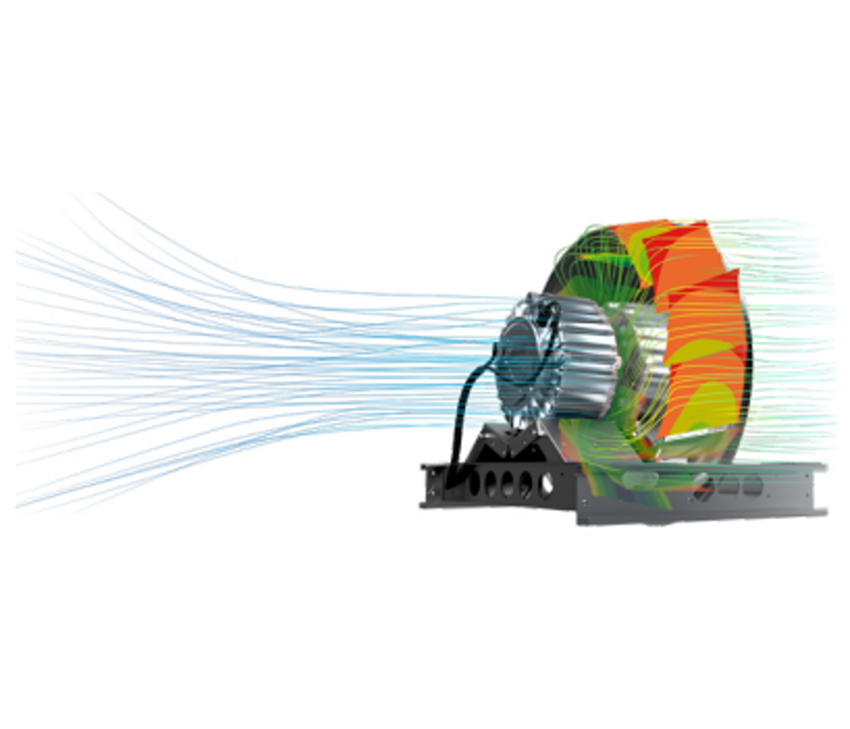

SFP is all about pressure and efficiency. To reduce the SFP there is a need to reduce pressure drop and increase the total fan efficiency.

![]()

A correct calculation of the SFP for the unit must include the leakages and the additional pressure needed to get a correct pressure balance.

The definition of SFPv demands that the leakages are included, and the operating points of the fans are calculated with the effects of leakage. This means that SFPv will be higher than SFP calculated without the leakage.

Read more in our blog about factors to consider when reducing SFP