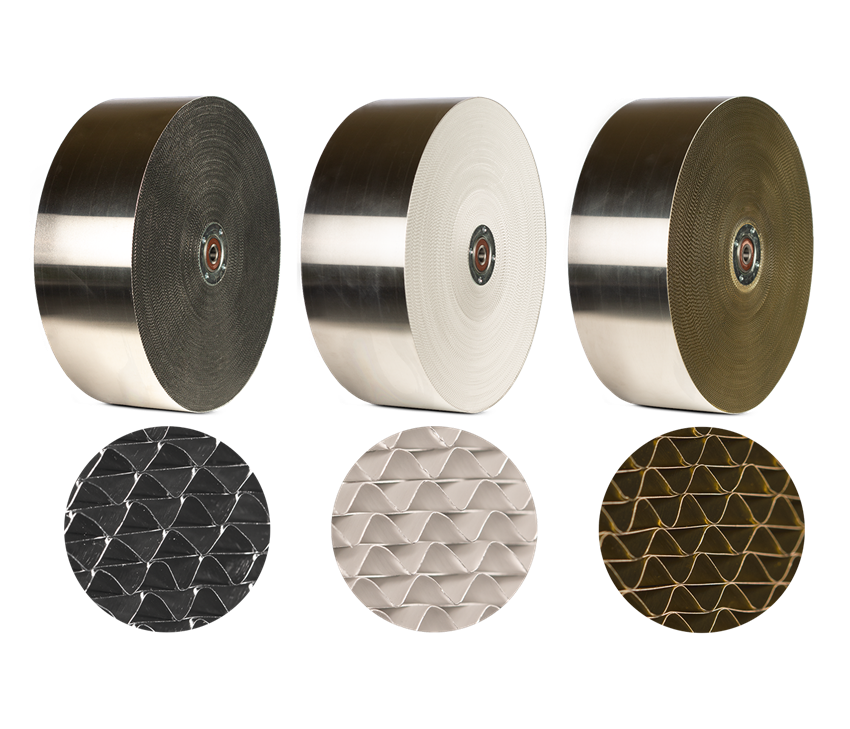

Types of rotors

Aluminium rotors are normally used in commercial buildings where temperature efficiency is most important. Sorption rotors are used when moisture is to be recovered for both summer and winter operations and epoxy rotors are used when there is a risk of corrosion attack, e.g. in coastal climates.

The rotor recovers both heat and cold, and with a sorption-treated rotor it also recovers moisture. During summer operations, the heat exchanger “dehumidifies” the outside air, which reduces the moisture precipitation in the cooling coil - the latent cooling capacity - and lowers the overall cooling capacity. This not only reduces operating costs, but also lowers investment costs and improves comfort in teh winter.

Winter operations usually mean a dry indoor climate, but a sorption-treated rotor recovers the moisture content of the extract air and increases the moisture content of the supply air.