The Passive House building certification

The Passive House standard may be seen as an entire concept, a whole-building approach, as it covers construction through to operation. It also includes construction materials and building infrastructure, such as ventilation units, which may be certified by the institute.

The exceptionally airtight construction required by the Passive House concept makes considerable demands on the building system for ventilating, heating and cooling to ensure a high level of comfort in the building.

From construction to operation

Passive House is a high-performance energy standard originating from Germany. However, the first typical building was completed in Canada in 1977, and combined airtightness, over-insulation and a system for heat recovery, highly unsual at the time. It was built in the context of an energy crisis with soaring oil prices.

The Passive House standard, established by the Passive House Institute years later, may be seen as an entire concept, a whole-building approach, as it covers the building from its construction through to operation. It also includes construction materials such as windows and building infrastructure, such as ventilation units, which may be certified by the institute.

The first Passive House like building

The energy consumption in the first building, that later may be called a Passive House building, was cut by 85% compared to an average building in the 1970’s. This, in part, due to the solar panels that were used to generate electricity, the insulated window shutters and the brown cedar siding of the building which absorbed heat from the sun.

However, energy was also saved by the means of a water heat exchanger for the production of domestic water and a ventilation unit with a heat exchanger for space heating, the first in residential use.

The first project in line with the Passive House standard, Kranichstein Passive House in Darmstad, Germany, was also Europe's first inhabited multi-family house to achieve a documented heating energy consumption of satisfying levels according to the standard.

Today

The concept has been around in its current form since 1990 when the Passive House Institute in Germany standardized a set of measurable key features that are now being used repeatedly. In addition to certifying buildings, the Passive House Institute certifies designers, builders, and materials, such as windows and ventilation units, used in passive house projects.

The passive house standard is applicable to both new-build and renovation projects. The latter is called EnerPHit and can be a useful means to reach today's targets for energy savings. The strategy called Renovation Wave, presented by EU in the year of 2020, stated that the building sector is responsible for more than one third of the emissions within the union and that roughly 75% of the building stock is energy inefficient. An estimation shows that 85-95% will still be standing in 2050. Having that said, energy efficient new-builds is not enough, substantial renovation efforts are needed reach agreed climate targets.

5 key characteristics

The institute's Passive House certification experts generally agree on 5 key construction and operation characteristics that result in exceptionally low energy consumption. These are:

1. Airtight construction

2. Insulation adapted to the climate

3. Thermal bridges reduced to a minimum

4. High-performance openings

5. Continuous ventilation (with heat recovery)

Better indoor climate if the biggest challenge is overcome

The exceptionally airtight construction required by the Passive House concept makes considerable demands on the system for ventilating, heating and cooling of the building. This because an airtight building needs to be provided with fresh air continuously to ensure a high level of comfort in the building and to dilute excess temperatures, airborne pollutants and excess humidity.

Continuous ventilation requires air handling units to operate whenever the building is occupied, and sometimes even when the building is empty. With that, they are often the greatest energy consumer in a building and should therefore be selected and specified based on their ability to ventilate, heat and cool in the most energy efficient way.

why is the indoor climate important?

There are numerous arguments to why the indoor climate is important. However, the three most critical are mentioned below.

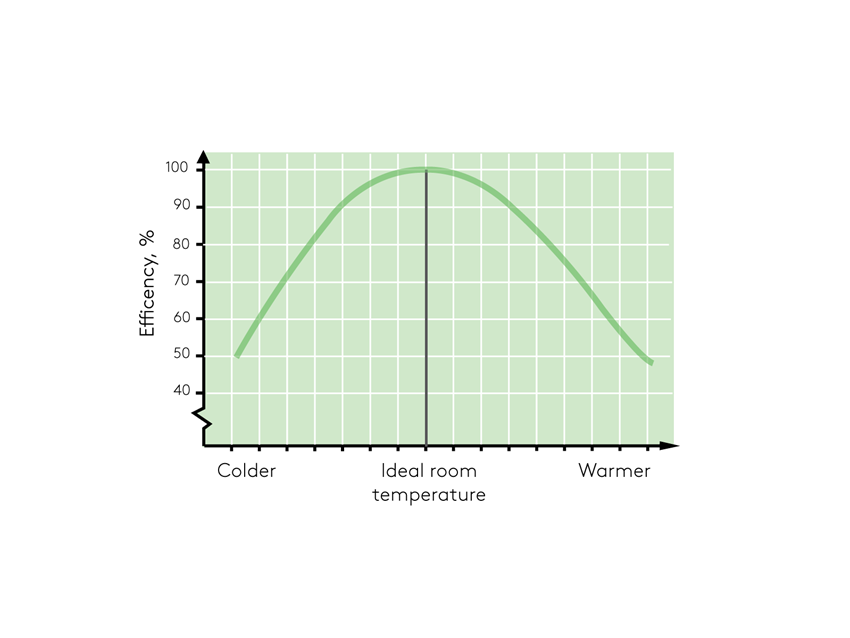

When the indoor temperature deviates from 21 degrees Celsius, performance of the people in the premises drops quickly (see graph to the left). A similar scenario is known in the context of levels of carbon dioxide (CO2) and strategic thinking. When reaching a level of 1000 ppm CO2 in the indoor air, more than doubled the concentration outdoors, the cognitive ability decreases drastically. Airborne particles is also a subject of consideration for indoor environments. This because buildings emit various sorts of small particles to which the human body has no natural defence. A controlled and optimised indoor climate allow the people in the building to be productive and well-reasoned, as well as healthy and comfortable.

More about indoor environmental quality at Swegon Air Academy

See our blog: What is IEQ and why is it important?Coming back to the heat exchanger

We spend about 90% of our time indoors, that is 21 hours a day. In the previous section a few aspects of the indoor climate were mentioned. In brief, it was made clear that the air we breathe impact our health and performance.

At the top of this page continuous ventilation, heat recovery and heat exchanger were mentioned. A double flow ventilation unit ensures continuous renewal of the air in a building which helps to eliminate CO2, pollutants and more. A rotary heat exchanger recovers heat through its multiple tiny aluminium pipes. The hot extract air warms the ducts and transfer the heat to the colder supply air when the heat exchanger rotates. The same applies for recovering cool energy, together it generates a high annual energy efficiency.

Our Swegon GOLD air handling unit with rotary heat exchanger is made for the task and is certified by the Passive House Institute.

Learn more in our guide about heat recovery

Humidity has an impact

As the Passive House concept focuses on both energy consumption and indoor comfort, humidity is a relevant factor to understand. In the summer, when the outside air is humid, it condenses as it cools which implies higher energy consumption. In winter, when the outside air is dry, issues with comfort arises in the form of dry eyes and dry upper airways.

Normally, the humidity level is between 20 and 40% in most buildings. The general recommended level is slightly higher, 30 to 60% depending on the season, but there are rarely any fixed limits.

An air handling unit with a RECOsorptic sorption treated heat exchanger improves the recovery of humidity from the extracted air, which enhances the level of comfort in the building. Humidity recovery also prevents the rotary heat exchanger from blocking due to frost, which further contributes to energy savings. In line with the Passive House standard.

Read more

Advantages of certifying a building according to the Passive House standard

Planning is the main factor to successfully achieve the Passive House certification. Only projects with a well-considered plan will ensure that all required factors are completed and comply with the standard.

A Passive House certification may be seen as an assurance of a building being of good standard. Airtightness, thermal bridges, the quality of the windows and their installation, the ventilation system and other building services are all verified as part of the certification process. So is the operation of the building, once the building services are installed and commissioned the entire project is assessed as part of the final certification.

Aside from the quality assurance and economical gains of the operation of a Passive House certified building, the design and construction process may benefit from highly knowledgeable architects and designers as well as high quality products.

Swegon expertise and products in Passive House projects

To express something in continouly updated numbers might be foolish. However, the fact that Swegon has supplied products and systems to almost a 100 Passive House projects world wide is worth mentioning, even if it is an outdated number tomorrow.

The products and systems from us at Swegon answer to a need or challenge with the aim of creating complete solutions for productive and healthy indoor environments. With such comprehensive approach both sustainability and energy efficiency has been thoroughly taken into account.

Swegon offers products that are EnerPHit certified components, Passive House certified for retrofit installation and use. Special demands are made on the performance of the these products, for instance on its power consumption, heat recovery, airtightness, sound level and flow control.

Read about our GOLD RX air handling unit below.

Source: www.https://passivehouse-database.org/

Products and solutions

The Passive House standard is a broad concept as it certifies both entire buildings and single products. The below are key products and systems from Swegon.