Free cooling or compressor cooling?

Free cooling is the process of using external ambient temperature to enable cooling and by that reduce, or possibly avoid, the use of a chiller. This can easily be described in the winter, when perishable foods can be placed in the cold outdoors and the nature’s free cooling is used for chilling instead of a refrigerator or freezer. Free cooling may in a similar way be used to lower the temperature of air or a refrigerant, and to avoid cooling by mechanical means. This saves energy. This guide will explain free cooling further.

Cold outdoor air provides free cooling

Free cooling may be used for both waterborne and airborne systems.

In its simplest form, outdoor air is used in airborne systems where a heat exchanger is fitted to treat the outdoor air before it is supplied to the building.

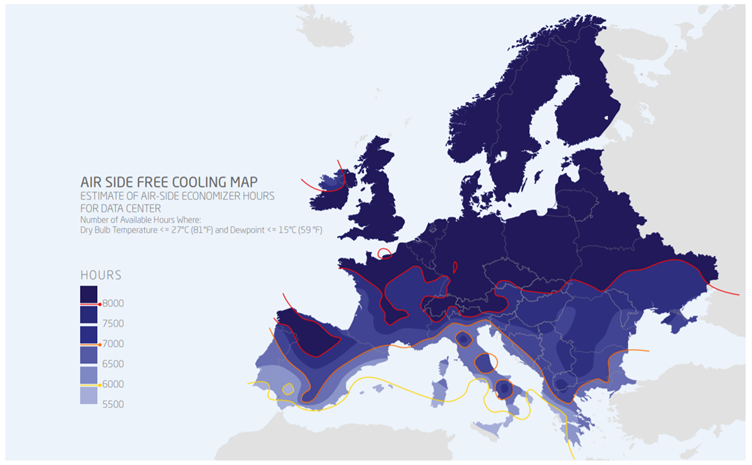

For this solution to be efficient, the air taken in must be cooler than the temperature aimed for indoors. It is optimal when the outdoor temperature is not exceeding 14-16 °C. The airborne free cooling method works very well in the Nordics since the outdoor temperature is below mentioned for about 90% of the year.

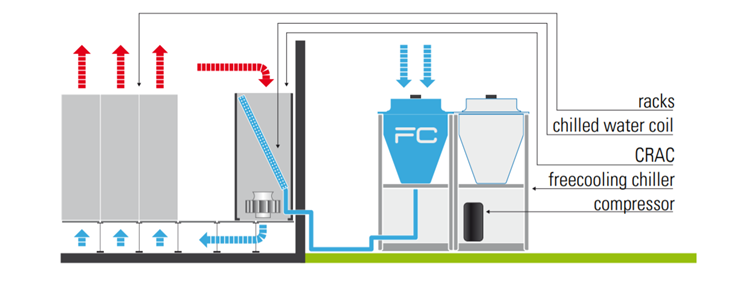

If a chiller using free cooling is provided to a waterborne system, the heat exchanger for the outdoor air is built into the chiller and placed between the refrigerant and the cooling medium circuits. When the outside air temperature is low enough to cover the required cooling, it is possible to operate without the power of compressors, hence almost cost free. This is called total free cooling.

For the above to work as efficiently as possible a three way valve is recommended to be used. It will manage the change from compressor cooling to free cooling, typically at an outdoor temperature around 10 °C.

Cooling by compressor – the traditional means to achieve cooling

Chillers are refrigeration systems designed to cool a fluid. This type of cooling is often called mechanical cooling or cooling by compressor. It is also what is usually meant when referring to unit cooling. Compressor powered chillers are flexible for cooling a building.

Cold fluid may be supplied to the cooling coil in an air handling unit which affects the temperature directly in all rooms as a complement to, for instance, chilled beams. This allows a better distribution of cooling. Or strictly, the expression of cooling being delivered to a building or room is actually incorrect. In fact, it is heat energy that is transferred away from the same. Let us explain.

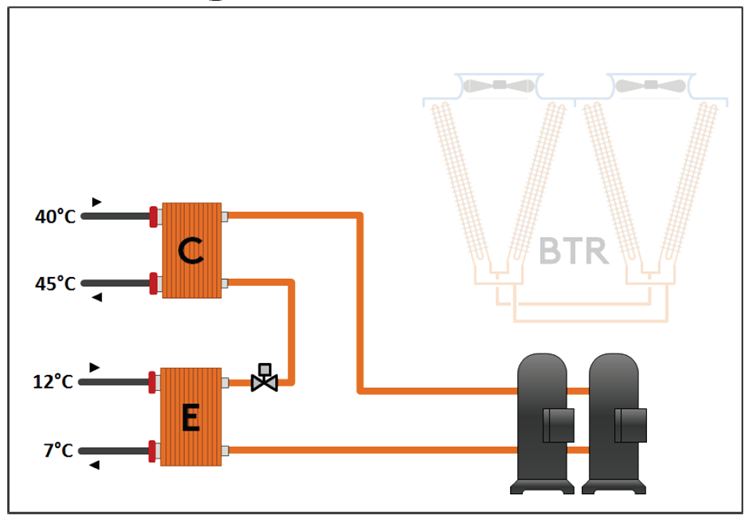

All chillers are based on a closed circuit filled with a refrigerant. The compressor increases the pressure and temperature of the vapour refrigerant. When the medium thereafter passes a heat exchanger/condenser, it condenses and reverts to its liquid state. The fluid then passes an expansion valve where the pressure is falling rapidly. This cools the refrigerant and the fluid is passed by yet another heat exchanger, called an evaporator. The evaporator works in the opposite way of the condenser, the refrigerant liquid is converted to gas, it absorbs heat from an external fluid and is then cooling it. This cooled fluid is subsequently directed to where it is needed in the building.

Heat pump and chiller refrigerant cycle

When cooling, electrical energy is being supplied to a compressor which then works to transfer heat away from one point to another, normally to the outdoors. In a heat pump, the opposite happens. Heat is transferred as energy from the outdoor air into the room. The outdoor air temperature then decreases and the cooling refrigerant is becoming the heating medium.

District cooling is more common

Cooling may also be distributed in the form of district cooling, supplied in large-scale to office complexes, shopping centres and other larger properties. This cooling may derive from free cooling, e.g. a cold lake, or from the energy in district heating that is being used locally to produce cold water. Comfort units placed in a room or space uses the water to produce the right temperature for the supply air in the system.

The above can be achieved, fully or in part, in a well-integrated system and reach a high TER, Total Efficiency Ratio, for both a chiller and heater respectively.

Is free cooling possible with an indoor unit?

In an air-cooled water chiller, the condenser is normally placed outdoors to be cooled by the means of outdoor air, a water-cooled water chiller has the condenser placed indoors. The latter is chilled by a dry cooler circuit which generally is located outdoors.

The free cooling may be used in winter to cool the refrigerant when the outdoor temperature is below its set-point temperature.

Partial free cooling

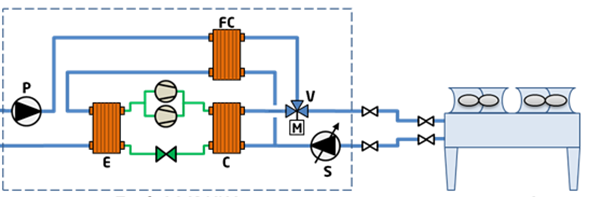

A unit with an option of free cooling requires a series of accessories, typically a 3-way valve, plate heat exchanger, controls and more, all specifically designed for the application. This level of integration permits full management of the system which enables the unit to operate in "partial free cooling" mode. This further allows very high efficiency levels.

With our waterborne units, the above may be achieved with built-in components and control functionality. This is a solution intended to enable optimisation and use of possible free cooling, but also be able to use compressor cooling.