Different methods for supplying air

The most common supply air solutions in premises for comfort ventilation are specified below. The maximum cooling loads that are specified refer to airborne cooling capacity and take into account accumulation in the building structure.

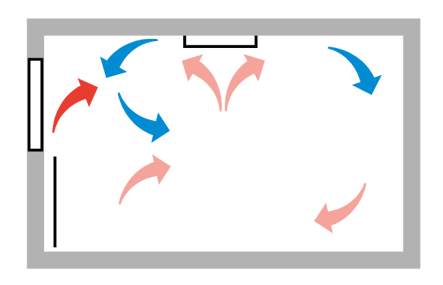

Ceiling placement

Using this method it is important to be precise in the definition of the occupied zone. In cases where downward air currents along the walls are acceptable, the principle has its clear advantages. Be aware of convection currents from the window wall.

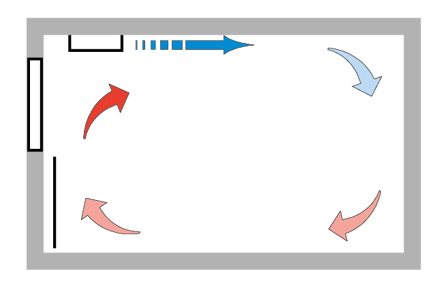

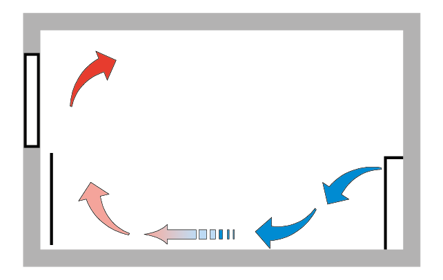

Ceiling placement, front edge

For supply air below room temperature, a satisfactory result from this method is usually obtained if the diffuser is scaled for a slightly longer throw length (1 to 2 m) than the room depth.

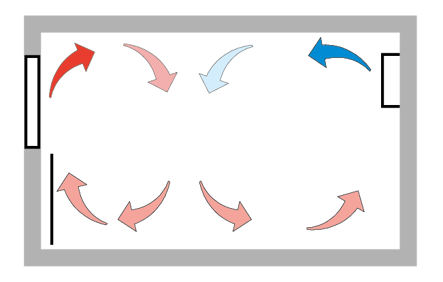

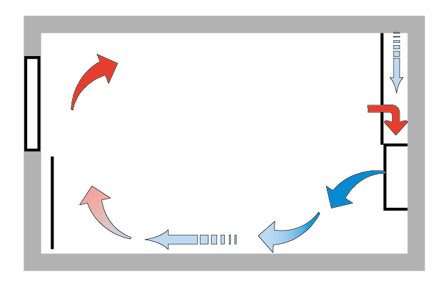

Rear edge placement

The selection of supply air diffuser is key in this solution, given the importance of the throw length. For example, an office where the workstation is located near the window wall, a maximum l0.2 should be equal to the depth of the room, multiplied by 0.7 when air below room temperature is supplied. Longer throw lengths may be used if the occupied zone does not go closer to the window than 0.75 m.

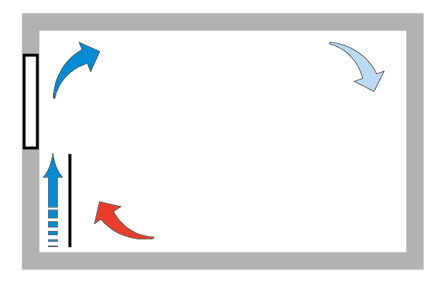

Window sill placement

It is important to recognise the case of supply air and window temperature. In situations where there is a risk of both these temperatures being lower than the ambient temperature, there is a also a risk of air plunges in the zone closest to the window (1 to 2 m).

Placement behind radiators

The placement in this solution requires a high outlet velocity from the supply air diffuser to prevent plunging in the occupied zone. It is important that any window sill is designed so as to not direct the air into the room.

Floor placement, low velocity

If diffusers with a flexible distribution pattern are used, a temperature difference between the room air and supply air of max 6°C may be applied in this method. Maximal cooling load is about 35 W/m2 at ceiling heights of approximately 2.8 m.

Floor placement, low velocity with ejector

Using a special ejector component as an add-on to the low velocity diffuser equalises the temperature distribution in the room’s occupied zone with this method. Temperature differences between 6 and 9 °C between the room and supply air can therefore be applied.